What are Diamond Core Drill Bits and Why should you use them?

Known as the most effective and efficient method of cutting tough materials, diamond core drill bits are widely used in tiling industry to drill holes in tiles. But what are diamond core drill bits and what are their advantages against other drill bits. Here are a few facts about diamond core bits.

What are diamond core drill bits:

Diamond core bits are drill bits that are welded with tiny particles of diamond, the toughest material known. As such these drill bits can cut through the hardest of tiles, including porcelain, ceramics, marble, granite and vitrified tiles.

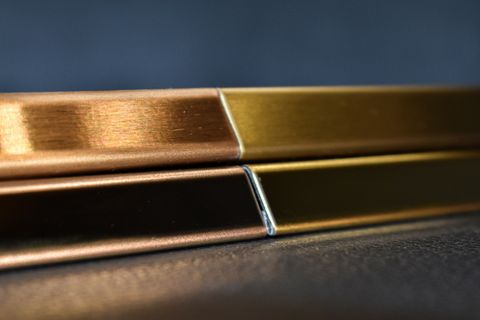

The most common methods of manufacturing diamond drill bits are electroplating and vacuum brazing. Vacuumed brazed diamond bits are manufactured by welding diamond particles in a vacuum brazing furnace of extremely high temperature. Vacuum brazed diamond bits are more durable, retain its sharpness for a longer time and can cut through harder tiles.

All OTEC diamond core bits by Amark Group are made using the vacuum brazing method to provide tilers with the most durable tools for precision drilling of tiles.

What are the advantages of diamond core drill bits:

- They can cut through the toughest of tiles: Diamond is the toughest materials out there. Compared to drill bits made from other materials, diamond drill bits can cut through tougher tiles like vitrified porcelain, granite and even concrete.

- Less debris and dust: Due to its immense cutting strength, diamond drill bits can cut through tough materials with ease, therefore produce less debris and dust during its operation.

- Diamond drill bits can be used with incredible speed tearing through everything from concrete to marble.

At Amark our OTEC Diamond Core Drill Bits can be used at up to 11,000rpm.

- Diamond Core Drill Bits make less noise: The speed and ease by which it can cut through strong materials means that diamond drill bits create much less noise during operation compared to other drill bits. Anything that can help reducing noise on a construction site is a big positive tick for us.

- Cost effective: As diamond is used in the making of diamond core bits, they might seem more expensive compared to core bits made from other materials. However, the durability of diamond core bits outlasts others and make these tiling tools a lot more cost effective in the long run.

- Good for the environment and for your health: minimal noise, minimal debris and dust make diamond core drill bits one of the most friendly drill bits for the environment and your health.

OTEC diamond core bits

At Amark Group, through many years of experience working with tilers and the tiling industry, we have developed a range of high quality OTEC diamond core bits:

- All our OTEC Diamond Core Bits are vacuum brazed to produce the toughest and highest quality core bits there are in the market.

- We have a large range of core bits, with sizes ranging from 5mm to 112mm. Either M14 or Hex adapters are available, so our OTEC core bits can be used in angle grinders or drills.

- OTEC Diamond Core Bits can be used at extremely fast speeds, up to 11,000rpm

- OTEC Diamond Core Bits also come in a set consisting of 7 x M14 Core bits in various sizes and 2 diamond milling bits, compact and easy to take to site, a perfect tool for any tiler.

For interested tilers, builders and contractors, you can buy our products from our distributors. Find the nearest one through our Stockist Search Page by typing in your suburb/postcode. The page will give you list of the nearest distributors in your area.

With Amark Group, you have easy access to the best products in the global tiling and stone cutting market. Download our buyers’ guide and register to be one of our stockists today.