Anodised or Powder Coated: Choose Your Aluminium Finish

They say that the devil is in the detail; the rule applies to tiling as well as paperwork. For a flawless tiled finish, details include professional grouting, straight tile cuts and a protective trim to elevate the visual appeal. Tile trims offer a clean and minimalist touch by concealing visible edges and providing a seamless transition to the door, window or to the floor of an adjacent room.

But the role of a tile trim goes beyond just aesthetics. In fact, the main purpose of covering the tile's exposed edges is to protect them from moisture, mould and anything that could cause damage.

Aluminium is one of the most popular materials for tile trims due to its strength, lightness and durability. It does the job of minimising impact on tile edges while serving its purpose as a decorative detail.

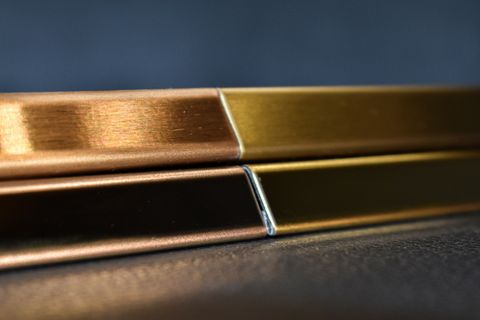

AmarkGroup's line of aluminium tile trims from Alltrim come in mill finish, anodised and powder coated finishes.

Anodised Aluminium

The anodising process involves the use of electrochemicals to further strengthen the aluminium's corrosion resistance by adding a layer of oxide on its surface. The process also provides better adhesion of paints and dyes, and allows aluminium to retain its natural physical properties.

Anodised aluminium requires minimal maintenance. Occasional cleaning with water and a mild detergent will bring back its original sheen. The oxide coating will not peel or flake from the material because it has become a part of the metal; the coating is translucent and lends a lighter effect on any colour. Retouching the colour of the trim is no longer necessary after anodizing ‒ the aluminium is protected from sunlight so colours don’t fade or lose their lustre.

The anodising process is also an environmentally friendly option as it does not emit any harmful volatile organic compounds (VOCs), nor are there any heavy metals involved.

Powder Coated Aluminium

Another aluminium finish is produced through a process called powder coating. The powder paint is applied using an electrostatic gun that creates a positive electric charge when it is sprayed on the grounded object. The electrical charge helps the powder to stick to the surface, and once it cures, it becomes part of the metal. There is a wide range of colours available in powder coating, and you can choose from matte, satin and glossy textured finishes.

The powder coating process is ideal for exposed tile trims in commercial environments. It provides the aluminium with industrial levels of strength against acidic and alkaline materials. Despite the dusty nature of the substance used in the process, powder coating poses no threat to air pollution.

High-Quality Tile Trims from Alltrim

At Alltrim, we supply anodised and powder coated aluminium tile trims that are ideal for a wide range of applications. Our anodised tile trims provide a decorative and protective finish, while our powder coated tile trims are chemically treated with a polyester finish. Alltrim tile trims are suitable for porcelain, ceramic and natural stone tiles.

Green solutions are at the heart of the Alltrim brand. We aim to provide high-quality products without presenting any threat to the environment.

Find the type you want from one of Australia's trusted tile trim suppliers. Contact us today.