Shop Now

-

Architectural Tile Trims

- L Profile Angle

- Square Edge Tile Trim

- Round Edge Tile Trim

- Shadowline Tile Trim

- Geometric Angle

- Patio Profile

- Balcony Edge Tile Trim

- Transition Edge Trim

- Ramp Trim

- Birdsmouth Tile Trim

- Slimline Corner Edge Trim

- Stair Nosing Trim

- Cove Trim

- Triangular Tile Trim

- Flat Bar

- Listello Decor Trim

- Tile Trim Corner Pieces

- Vinyl Trim

- PVC Angle

- T Profile

- Movement Joints

-

Tiling Tools

- Electric Mixers & Paddles

- Suction Cups

- Grouting Tools & Floats

- Notched Trowels & Scrapers

- Spirit Levels

- Grout Removers

- Gauging & Square Front Trowels

- Sponges & Clean Up Sets

- Safety & Protective Equipment

- Kneepads

- Measuring & Marking Equipment

- Knives

- Diamond Hand Pads

- Tile Nippers

- Caulking Guns & Applicators

- Straight Edges

- Rubber Mallets

- Paint Brushes & Rollers

- Tile Trim Shears

- Hot Melt Glue Guns

- Lambswool Applicators

- Cleaning Wipes

- Polishing Pads & Wheels

- Packaging Materials

- Diamond Blades

- Hole Cutters

- Manual Tile Cutters

- Electric Tilesaws

- Large Format Cutting & Lifting

- Tile Spacers

- Tile Levelling Systems

- Floor Wastes & Drains

- Tile Pedestals

Latest Posts

-

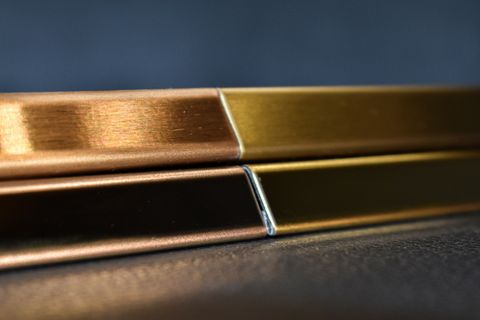

The difference between Natural Brass and PVD coated Stainless Steel Gold Trims

Date: 31-01-2023Are you after gold trims for your wet areas but don't want the aged look of natural brass? Here are some handy tips. -

What to consider when looking for a tiling tool supplier?

Date: 10-06-2021Looking for a reliable Tiling Tool supplier to ensure you are never out of stock of quality tiling tools and equipment? Here are what you need to know. -

Large format tiles – what to know about this current design trend

Date: 11-05-2021Large format tiles are one of the hottest design trends right now. Explore their benefits and what to consider when install large format tiles.

How to use diamond blades safely

Diamond blades should be handled with utmost care at all times. These tools are not just handy and efficient; using them can be hazardous, too.

Safety should be a priority whenever you are using diamond cutting tools. The consequences of improper use are inconvenient at best and very grave at worst.

Here are some safety guidelines when using diamond blades:

Wear proper protective equipment at all times.

Before you begin, make sure that you are equipped with proper safety gear. This includes the following:

- Non-fogging and amply vented safety goggles and headgear

- Snugly-fitting clothes that do not disturb the free movement of your hands

- Sturdy gloves and robust boots with non-slip soles

- Proper respiratory equipment

Refrain from wearing accessories to prevent injury and accidents.

Install the blade properly.

Be careful not to spin the blade in the wrong direction. The blade can still cut if it is turning the wrong way; however, the diamonds will be eaten up faster.

Pay attention to the directional arrows labelled on the blade, to ensure that the product is installed correctly and spins in its intended direction.

Use the right blade for the right job

There are specific types of diamond blades for concrete and masonry. General purpose blades can cover a range of cutting tasks; however, application-specific blades are engineered to meet the needs of a specific job.

When choosing the right blade for a specific task, you need to identify the material you will be cutting, which type of cutting equipment will be used, the amount of cutting that needs to be done and how fast you need to finish the job.

We have prepared a helpful guide for you to know which specific blade is best suited for a particular type of material.

Use a wet blade only when the surface is wet.

Wet cutting involves using water as an assistive agent in cutting through thick tiles, reinforced concrete, bricks and other masonries. Dry cutting, on the other hand, is meant for intermittent and shorter-scale cutting.

Keep in mind that wet blades are not meant for dry cutting. The friction of concrete and asphalt can rapidly burn up the blade when used dry. In contrast, dry blades can be used wet, and doing so can increase worker productivity and the blade’s lifespan.

Our product range includes blades that can be used for both wet and dry cutting. Our diamond tools are designed for durability and improved productivity, and our products deliver high precision and quality results.

Amark Group is your one-stop shop for tiling tools and equipment

We are a trusted name for diamond tool supply in the tile and stone industry. Our company provides the most comprehensive range of tiling products in Australia.

Because we are dedicated to providing excellent service to our clients, we continuously source new tiling products from around the world. We want to give our customers access to a global network of reputable manufacturers and suppliers.