What Makes a Durable Diamond Blade?

Concrete is one of the world's leading building materials. It is used in huge numbers of construction projects due to its durability and versatility. When working with concrete, or any similar hard material, it's important that you should always have the right tools to make work effortless, efficient and safe. A high-quality saw blade, especially a diamond blade, is one of the most useful tools in sawing contraction joints and cutting decorative patterns.

Diamond blades use friction between the blade and the material being cut to work just like an abrasive grinding wheel. However, when it comes to making clean cuts, diamond saw blades are more beneficial than abrasive wheels.

Here are the four major components that make a diamond saw blade durable:

Diamond Crystals

The diamond used in the sharp edge of the blade is synthetic or manufactured as opposed to a natural material. The synthetic diamond is used rather than natural diamond since its key characteristics such as size, durability and crystal shape can be controlled through the manufacturing process. Controlling the key characteristics of the diamond enables prolonged blade life and accurate prediction of cutting speed.

Metal Bond

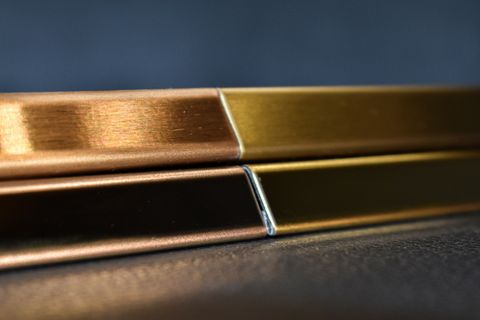

The metal bond is a mix of metal powders used in various configurations to achieve specific wear rates. A well-formulated metal bond holds the diamond crystals in place. There are two kinds of metal bonds: soft and hard bonds. Soft bonds are made up of soft metals such as bronze. Diamond blades with soft metal bonds are used for cutting less abrasive materials like porcelain. On the other hand, diamond blades with hard metal bonds are made up of hard metals such as tungsten carbide. These blades are usually used to cut soft materials such as fresh concrete and asphalt.

Diamond Edge

To form the diamond edge, both the crystals and the metal bond mix are heated, shaped and placed to the blade's core. The edges are attached to the core through sintering, brazing or a laser welding process. The diamond edge can be made to various configurations such as serrated, segmented or continuous rim, each was designed for a particular cutting purpose.

Diamond edges are wider than the blade's core to reduce damage on the blade and decrease the chances of the blade binding with the material being cut.

Steel Core

A diamond blade's steel core is the round flat metal disc that supports the edge. It is usually made of a high alloy, heat-treated steel that's tensioned to enable the blade to turn easily on the arbour hole. The core is also made to reduce high pressure caused by the force and impact when cutting dense materials.

What to consider when buying a diamond blade?

A diamond blade is an investment that you want to last. Choosing the right blade for what your project needs is the first step to ensure its durability. The blade manufacturers normally have information of what are the best uses for their products.

Stay with reputable brands with products that are tested and tried. Cheaper options might end up costing you a lot more if they only last for a short period of time.

Finally, look after your tool. Clean them as per manufacturers instructions.

Looking for the right diamond blade? Talk to the expert

Amark Group can help. We have a large diamond blade supply in stock such as stainless steel cutting blades and continuous diamond blades. Our blades are suitable for many types of cutting machines to ensure accurate cutting. Our range of diamond blades is sourced from reliable brands in the industry such as Otec.

When you use our diamond blades, you can be confident that they can cut many types of material such as porcelain, glass and natural stone. They are also suitable for dry and wet cutting to meet the needs of various industries.

For more details on our diamond blades, call 1800 804 297.